French fries production line

خانه » French fries production line

French fries production line

French fries is one of the most popular and profitable new products in the food industry, and today, specialized machines and production lines are continuously being developed and improved to enhance both the capacity and quality of this product. The food industry is experiencing fundamental changes in the present day. Compared to the past, the food industry has made significant strides worldwide, producing a wider variety of higher-quality products due to increased productivity and advanced food processing techniques. Each day, new product varieties are introduced to the market.

French fries, as a product of its production process, boasts a remarkable taste and quality, and it has an extraordinarily low oil absorption rate, making it one of the most consumed and health-conscious products.

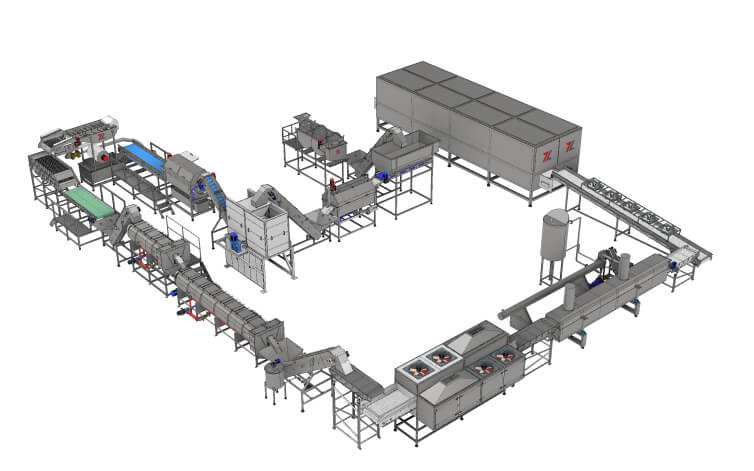

Zagros Tav Machine Company operates nationwide in Iran, specializing in the design, manufacture, installation, and modernization of complete production lines and factories, as well as special machinery for French fries production using semi-ready frozen potatoes. The company employs state-of-the-art knowledge and cutting-edge technologies in this field, offering advanced technological solutions beyond simply providing the necessary machinery. This company customizes the design and manufacturing of French fries production lines according to your specific capacity requirements.

For a comprehensive production line, our company provides the installation and commissioning of individual quick freezers, boilers, and packaging machinery, if desired.

French fries production process

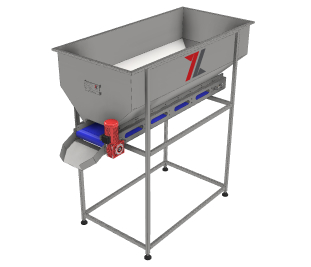

The process of producing French fries typically involves the transfer of potatoes from the raw material storage warehouse (potato warehouse) to a sorting area. In this area, only potatoes of the correct size are allowed to enter the production line. At the beginning of the production line, the potatoes go through a washing machine to remove stones and dirt. Subsequently, they are transported to a peeling machine via a conveyor belt to begin the peeling process.

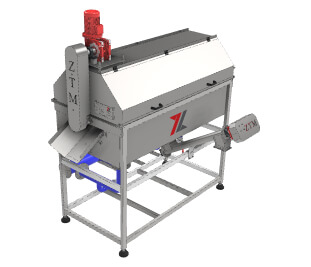

In the peeling machine, a tank with high-pressure steam is used to separate the potato peel. For lower-capacity operations, abrasive peelers can be employed to reduce costs. Following the peeling process, the potatoes exit the steam peeler and proceed to a brushing machine to remove any remaining peels on the potato's surface. The peeled potatoes are then moved to an inspection conveyor for human agents to inspect and separate damaged or stained potatoes, removing them from the production process.

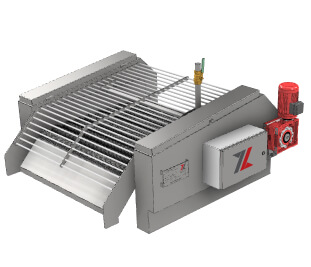

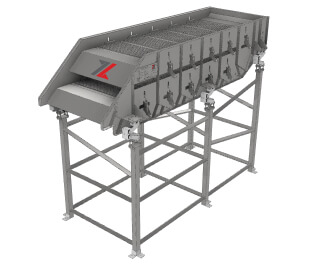

After passing through the conveyor, the fresh and properly-sized potatoes enter the hydro cutter machine, where they are cut into French fries slices. For lower-capacity systems, a mechanical cutter may be used, especially in case of hydro cutter blade failure or replacement. Due to the oval shape of the potato, the slices cut from the corners tend to have shorter lengths and smaller thicknesses. To ensure consistent product quality within the packaging, these potato slices are sorted using a longitudinal sorter and a waste separating sorter, with only suitably sized pieces proceeding in the production line. To further eliminate any blemished or ruined potatoes from the production process, they are transferred to an inspection section and manually sorted. Subsequently, the fresh and uniform potato slices are conveyed to primary and secondary blanchers for starching, enzyme stabilization, and tissue cohesion, preparing them for the frying process.

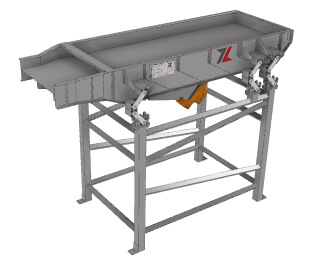

The water temperature and the duration of the potatoes passing through the primary and secondary blanchers are critical to achieving the desired outcome. Before frying, the blanched potatoes are sent to a dryer to remove excess moisture. In the fryer, the potatoes are cooked in oil at a specific temperature and for a specific duration. After frying, they are transferred to a vibrating system to remove excess oil.

To complete the production process, the fried potatoes pass through a pre-cooling system to lower their temperature before entering an Individual Quick Freezing (IQF) tunnel. After full freezing, the product is conveyed to the packaging area. Frozen French fries are typically packaged in 2.5-kg, 900-g, or 750-g packages, placed in cartons, and then transferred to a cold storage facility set at -18 degrees Celsius for preservation.

French fries line production capacity

Production lines for French fries can generally be categorized into two groups based on their capacity: low capacity and high capacity. In the low-capacity group, the production line has an output of 500 kg per hour, while in the high-capacity group, the production line can yield anywhere from 1,000 to 15,000 kg per hour. Depending on the available space in the production facility and the investment budget of the customers, Zagros Tav Machine Company custom designs and manufactures French fries production lines. These production lines are tailored to meet the varying capacity needs of customers, offering cost-effective solutions and comprehensive packages that address the essential aspects related to quality production and the efficient utilization of machinery in the French fries production line.

Zagros Tav Machine Company specializes in the design and manufacturing of fully automated French fries production lines, particularly those with low capacity, providing a production line that adheres to European standards.

We are committed to supporting you throughout the entire journey to success.

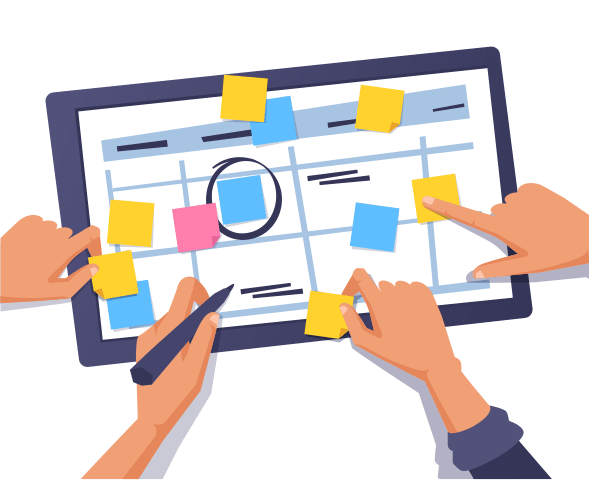

Our dedicated project management team ensures the timely delivery of your machines without compromising on quality. Before the construction of your machines commences, we will engage in a thorough consultation to confirm the specific requirements of your project. We will finalize the construction schedule, layout plans, and materials, and even create a simulated model of your machines. We provide you with the tools necessary to guarantee a successful end result.

A dedicated project manager will be assigned to oversee the progress of your project and maintain open communication with you to ensure that the specifications of your machines are met and that the delivery occurs as planned. We understand that our success is intertwined with your success.

All of our project managers are deeply committed to the company's mission, pay attention to the finest details, and are fully invested in the success of each project.

Our goal is to make continuous progress not only in the production of machines, but also in the production processes of output products, even with a decade of experience, so that you can benefit from high productivity and efficiency.

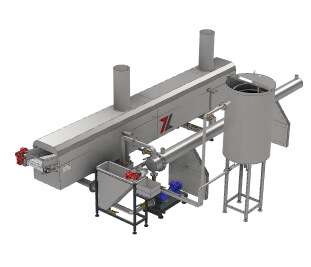

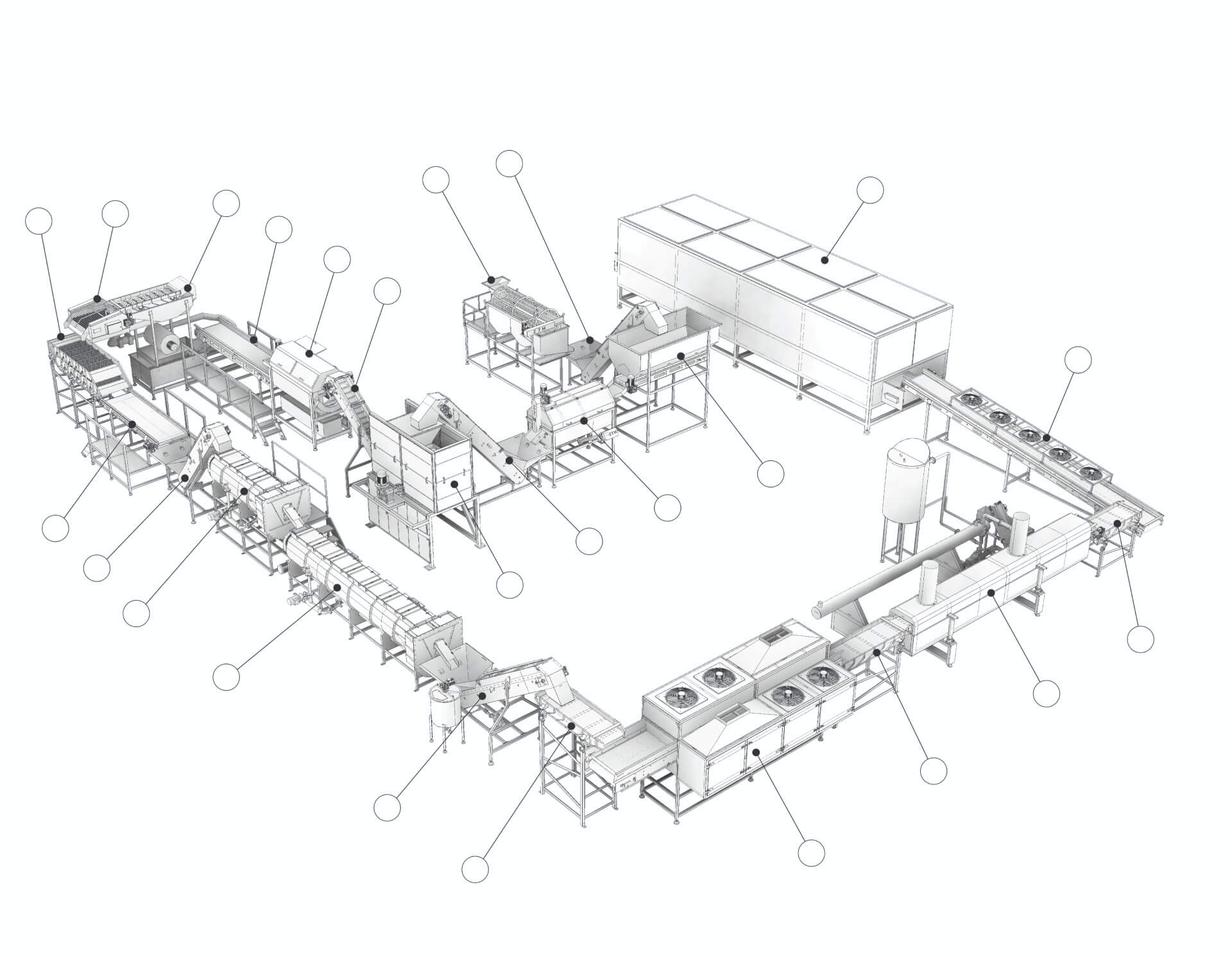

Arrangement of machines for the production and processing of French fries (semi-ready frozen potatoes)

Oil extractor

Pre-cooling equipment

IQF tunnel freezer

چیدمان ماشین آلات خط تولید و فرآوری فرنچ فرایز (سیب زمینی نیمه آماده منجمد )

-

Packaging

Packaging

-

Hot oil boiler

Hot oil boiler

-

Steam boiler

Steam boiler

Zagros Tav Machine has meticulously designed all the machines for the French fries production line in alignment with the latest European design and technology standards. Driven by our dedication and expertise, we are striving to establish exemplary industrial facilities for your benefit.

Your success is our success, and we are fully committed to supporting you every step of the way to attain our shared goals.

Arrangement of French fries production line with a capacity of 500 kg

Arrangement of French fries production and processing line with a capacity of 2000 kg

Full video of semi-ready potato production and processing line

French fries potato processing production line made in Iran

Used devices

Free consultation

Contact us to get free consultation and get more information about production lines and related equipment

Sales Manager:

+989124408722

Central office:

+9821-48813800

+9821-48813801