We are a manufacturer of equipment and production lines for the food industry

Our expertise is in designing and manufacturing equipment and production lines for the food industry

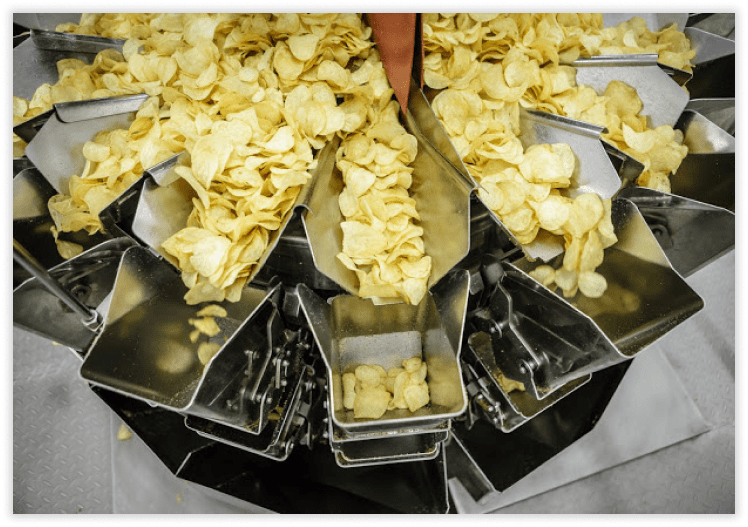

Fryer

Designing and manufacturing all kinds of fully automatic fryers for frying chips, French fries, peanuts, etc.

Blancher

Designing and manufacturing different types of blanchers with different capacities for potatoes, vegetables and etc.

Steam peeler

Designing and manufacturing all kinds of peelers with different capacities in the form of steam or abrasion

Dryer

Designing and manufacturing all kinds of industrial dryers with different capacities for products such as French fries, cheese puffs, nuts, seeds, etc.

French fries production line

French fries are among the most popular, healthy, and profitable products in the food industry. Today, machines and production lines for French fries are continuously evolving and improving to enhance product capacity and quality. The food industry is currently undergoing significant changes, with remarkable progress and increased productivity. It now produces a wider range of diverse and higher-quality products compared to the past. Zagros Tav Machine Company operates across Iran, specializing in the design, production, installation, and factory upgrades for French fries lines (semi-ready frozen potatoes). We use the latest information and cutting-edge technologies in this field to deliver complete production lines. Additionally, our company offers the installation and commissioning of individual quick freezers, boilers, and packaging equipment to complement your production line. Zagros Tav Machine Company designs and manufactures machines and French fries production lines with capacities ranging from 500 kg per hour to 15,000 kg per hour, all in a fully automatic manner.

We stand with you every step of the way towards success

Our project management team ensures the timely delivery of your machines, maintaining quality, and even improving product performance. Before commencing construction, we collaborate with you to finalize specifications, materials, provide a simulated model of the machinery layout, establish construction schedules, and offer a clear plan for the end result.

A dedicated project manager is assigned to oversee your project, closely communicating with you to ensure machine specifications are met and deliveries are on time. We understand that our success is contingent on your success.

All our project managers are deeply committed to our company's work, paying meticulous attention to details, and investing in the success of each project. Our goal is not only to advance machine production but also to enhance the processes for producing end products. With over a decade of experience, our aim is to help you achieve high productivity and efficiency.

About Zagros Tav Machine Company

Zagros Tav Machine Company is actively engaged in designing, manufacturing, implementing, and operating machines and processing lines for semi-ready frozen potatoes, specifically French Fries. By employing experts in engineering units with the highest knowledge of mechanisms and design, the company strives to offer top-quality products in Iran. At present, the company, with an experienced technical engineering team, designs and manufactures machines for this line using the latest technology. It also provides continuous after-sales advice and services to its customers, establishing itself as a leading and well-known brand in this industry. Before constructing each machine, the company's designers provide a 3D simulator to give you a comprehensive picture and understanding of the implementation. Additionally, the team is responsible for arranging and positioning machines for French fries processing lines in factories. The company's research and development (R&D) group ensures that the technology and standards of all machines in this line are consistently updated to provide customers with the best and most up-to-date equipment in the world. It's important to note that all cutting work is done using laser technology, and parts are bent using CNC Press Brake machines to offer the best quality. Furthermore, through annual courses for specialized personnel, Zagros Tav Machine Company aims to harness the best available skills for producing food industry machinery and to keep its technical and specialized personnel's knowledge up to date.

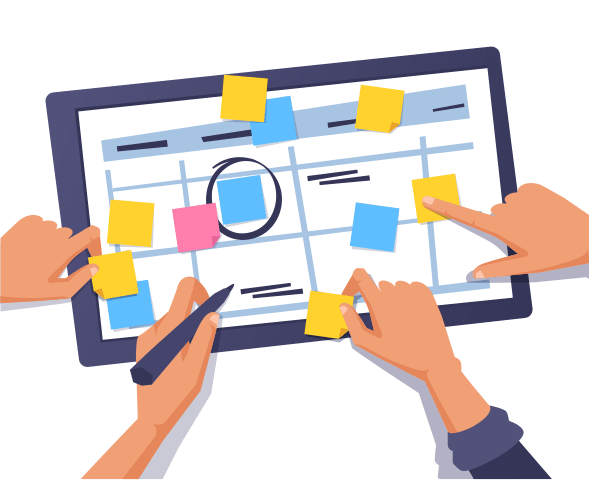

Packaging

In today's world, product packaging plays a crucial role in product sales and presentation to the market. The type of packaging and its attractive and suitable design are essential for making a product stand out among the multitude of products on store shelves and attracting customers. In this context, choosing a quality packaging machine and appropriate packaging design are the two primary factors for achieving this. Today, multi-head weighing systems are the most common and up-to-date type of weighing system globally, offering superior accuracy and speed compared to older-generation weighing machines.

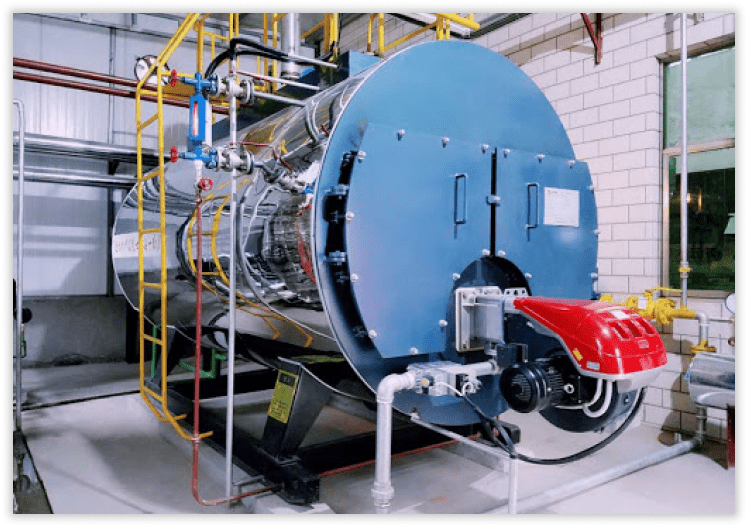

Boiler

A boiler is a pressurized vessel used to heat fluids to the desired temperature. In general, a boiler is a equipment responsible for boiling or heating a fluid. Boilers are categorized into various types based on the heating method and the heating fluid. Some of the well-known and widely used types include steam boilers, hot oil boilers, hot water boilers, and hot air boilers. In potato chips and French fries production lines, hot oil boilers are employed to heat edible oil, blancher water, and provide the necessary steam for steam peeling.